Carbon fiber is a highly advanced material utilized in aerospace, medicine, construction, fashion, with numerous benefits and applications.

Together, Fashion Bandung is exploring the world of Carbon Fiber Fabric. We will delve into what exactly Carbon Fiber Fabric is and why it is gaining popularity in various industries. Additionally, we will examine the advantages and disadvantages of using Carbon Fiber Fabric in different applications. Furthermore, we will investigate the durability of Carbon Fiber Fabric and its ability to withstand various conditions. Stay tuned as we unravel the mysteries of this innovative material.

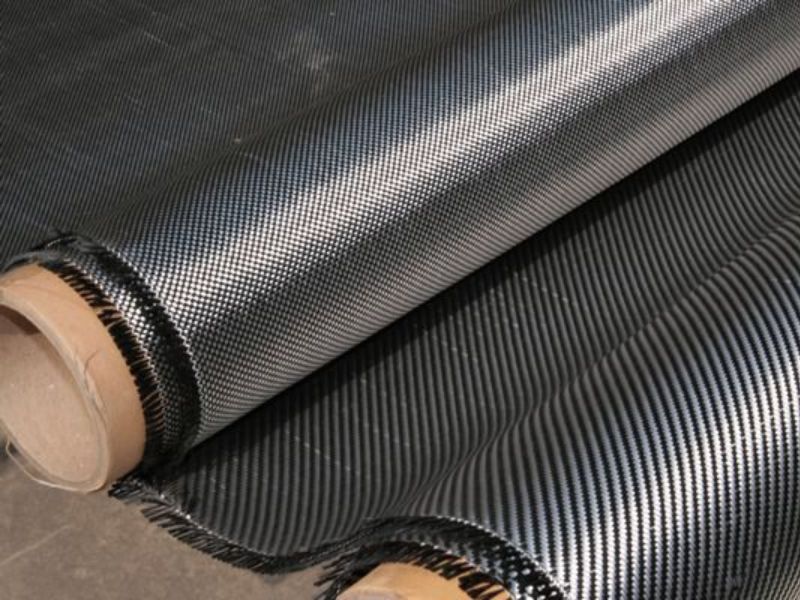

What is Carbon Fiber Fabric?

Carbon fiber fabric is a type of fabric that is specifically composed of carbon fiber. Carbon fiber itself is known for its remarkable strength and incredibly low weight. The production of carbon fiber involves the carbonization process of synthetic fibers like polyacrylonitrile (PAN), rayon, or cellulose fibers derived from bamboo. During carbonization, these fibers undergo a transformation, becoming exceptionally rigid and gaining excellent resistance to heat and strength.

Carbon fiber fabrics have widespread applications in various industries that demand exceptional stiffness, strength, and heat resistance. Notably, they are extensively utilized in the aviation and aerospace sectors, where lightweight yet robust materials are crucial. Additionally, carbon fiber fabrics find application in manufacturing racing cars, as they provide the necessary strength and durability required for high-performance vehicles. Moreover, these fabrics are also employed in sports equipment, enabling the production of resilient and lightweight gear. In the medical field, carbon fiber fabrics are indispensable for creating support structures in surgical procedures and medical devices, ensuring stability and reliability.

Carbon fiber fabric is considered one of the most advanced and cutting-edge materials in the 21st century. However, its price is relatively high compared to other materials. On average, the cost of 1 square meter of carbon fabric can range from 1,500,000 VND to 2,800,000 VND, depending on the specific type of carbon fabric.

Carbon fiber fabric is a type of textile that is composed of carbon fibers. These fibers are extremely thin and are made from carbon atoms that have been bonded together in a specific pattern. The fabric is known for its strength, durability, and lightweight properties. It is commonly used in various industries, such as aerospace, automotive, and sports, where high performance and rigidity are required. Carbon fiber fabric is often used in the manufacturing of products such as aircraft parts, automobile frames, and sporting equipment.

Traits of Carbon Fiber Fabric

Advantage

Carbon fiber fabric is highly valued and extensively utilized in various essential industries due to its multitude of exceptional advantages that set it apart from other materials. When considering whether carbon fiber fabric is commendable, one must take into account its outstanding features which are enumerated below:

- Super light: With an ultra-low density of 1.5g/cm3, carbon fabric is much lighter than conventional materials.

- Stiffness: Carbon fiber fabric has the ability to provide high stiffness while remaining light weight. This makes it an ideal material for applications that require low weight and good mechanical properties.

- Super strong and durable: Carbon fiber fabric can withstand high loads, including tensile, compressive and bending loads. At the same time, carbon fiber fabric has 5 times the strength and 2 times the stiffness of steel. This makes it a popular material in the production of parts and structures that require high strength.

- Good heat resistance: With the ability to withstand heat up to hundreds of degrees Celsius, carbon fiber fabric is suitable for applications requiring high heat resistance such as in aviation and aerospace.

- Good corrosion resistance: Carbon fiber has good resistance to corrosion and chemical erosion, helping to maintain performance in harsh environments.

- Easy to cut and shape: Carbon fiber fabric can be easily cut and shaped according to the specific requirements of applications.

- Conductivity: Carbon fiber has good electrical conductivity, so it is often used in creating conductive structures such as in electronic circuits or anti-static applications.

Carbon fiber fabric is a highly versatile material known for its exceptional properties, which contribute to its widespread use across various industries and applications. Its popularity stems from its remarkable characteristics and performance in diverse settings.

There are several advantages of using carbon fiber fabric. Carbon fiber fabric is known for its high strength-to-weight ratio, making it incredibly strong while still being lightweight. It is also highly durable and resistant to corrosion and fatigue, allowing it to maintain its performance over an extended period of time. Additionally, carbon fiber fabric offers excellent thermal and electrical conductivity, making it suitable for a wide range of applications. It is also highly flexible and can be molded into a variety of shapes and sizes, making it versatile for different uses. Lastly, carbon fiber fabric has a visually appealing aesthetic, giving products a sleek and modern look.

Defect

Despite having numerous exceptional advantages, it is undeniable that this material also possesses a few drawbacks.

- Brittleness: Although it has high strength, carbon fiber is brittle and can break easily.

- Difficult to recycle: Carbon fiber can be recycled, but the recycling process is difficult and complicated.

As a result, this particular material is deemed to have a low level of environmental friendliness.

One of the drawbacks of carbon fiber fabric is its relatively high cost compared to other materials. The production process for carbon fiber fabric involves several intricate and time-consuming steps, which contribute to its higher price. Additionally, carbon fiber fabric requires specialized equipment and expertise for manufacturing, further adding to the production costs.

Another disadvantage of carbon fiber fabric is its susceptibility to damage from impact. Unlike traditional materials like steel or aluminum, carbon fiber fabric is more prone to fractures or cracks when subjected to a significant force or impact. This can limit its use in applications where durability and resistance to impact are crucial, such as in the construction of heavy machinery or vehicles.

Furthermore, carbon fiber fabric can be challenging to repair. Once it sustains damage, fixing or mending the fabric can be a complex process that requires specialized skills and expertise. In some cases, the damaged section may need to be completely replaced, adding additional costs and time to the repair process.

Moreover, carbon fiber fabric has certain limitations in terms of heat resistance. While it has excellent thermal conductivity properties, carbon fiber fabric can experience thermal degradation when exposed to high temperatures. This restricts its use in applications where it may encounter extreme heat, such as in aerospace or automotive components that may be subjected to intense heat during operation.

Lastly, carbon fiber fabric is not as readily available as other conventional materials. Its limited availability and the specialized manufacturing processes required to produce it can pose challenges in obtaining the desired quantity of carbon fiber fabric. This can lead to longer lead times and potential delays in projects that rely on this material.

Overall, while carbon fiber fabric offers numerous advantages such as its lightweight nature and exceptional strength-to-weight ratio, it is important to consider these disadvantages when deciding on its use in various applications.

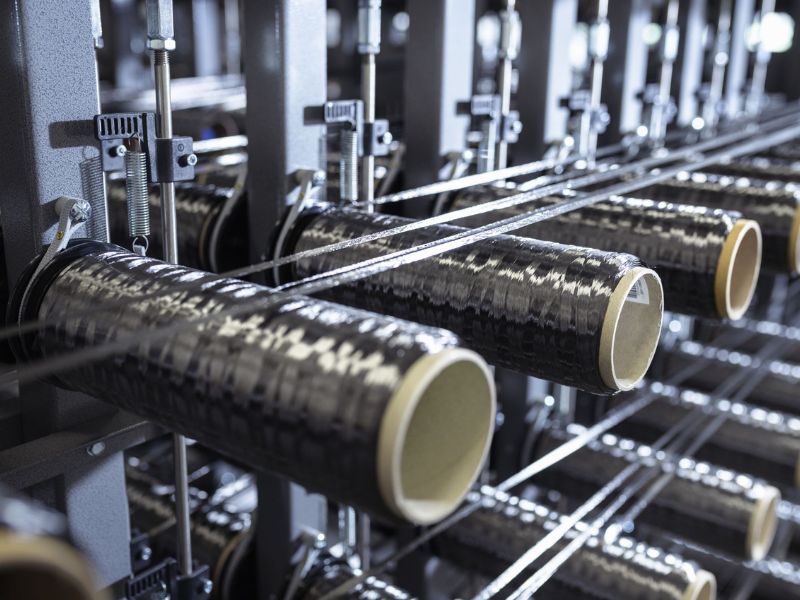

What is the process of manufacturing carbon fiber fabric?

The production process of carbon fiber fabric involves several key steps.

- Raw material preparation: The main raw materials for carbon fiber production are synthetic fibers such as polyacrylonitrile (PAN), rayon, cellulose fibers from bamboo, cellulose, graphite or pitch. These fibers are cleaned and treated before entering the Carbonization process.

- Carbonization Process: In this process, the synthetic fiber is placed in an oxygen-free atmosphere and heated at high temperatures (between 1000 and 3000 degrees Celsius) for a long period of time. This process creates carbon fiber by removing most of the other elements and retaining only carbon.

- Surface treatment: After carbonization, carbon fibers can be surface treated to improve adhesion and compatibility with other materials during fabric production.

- Weaving or Stamping: Carbon fibers are woven or stamped together to form a fabric structure. Common weaving techniques include weaving carbon fibers on traditional looms or using modern techniques such as Jacquard weaving or circular weaving.

- Technical processing: After the fabric is formed it can be further processed to improve its strength, flexibility and other properties according to the specific requirements of each application.

- Quality Control: Finally, the carbon fiber fabric is quality tested to ensure that it meets the standards and specifications.

The manufacturing process of carbon fiber fabrics is intricate and requires a high level of technical expertise. There are numerous variations of this process, which are tailored to suit different applications of the fabric.

The process of manufacturing carbon fiber fabric involves several steps. First, carbon fiber is produced by heating and stretching carbon filaments. These filaments are usually made from a precursor material, such as polyacrylonitrile (PAN) or pitch, which undergoes a series of treatments to create long, thin carbon fibers.

Once the carbon fibers are prepared, they are woven together using specialized machines to form a fabric. The weaving process can vary depending on the desired characteristics of the final product. Different weaving patterns, such as plain weave, twill weave, or satin weave, can be employed to achieve specific strength, flexibility, or aesthetic qualities.

After weaving, the carbon fiber fabric undergoes a stabilization process to ensure dimensional stability and eliminate any remaining volatile components. This is achieved by subjecting the fabric to heat in the presence of an oxidizing agent. Stabilization converts the carbon fiber into a rigid, heat-resistant material that can withstand subsequent processing steps.

The next step is carbonization, where the stabilized fabric is exposed to extreme heat in the absence of oxygen. This process further strengthens the carbon fibers and removes any remaining non-carbon elements from the fabric. Generally, carbonization is performed at temperatures exceeding 1000 degrees Celsius.

Once carbonized, the fabric may undergo additional treatments, such as surface coating or impregnation with a resin matrix, depending on its intended application. These additional steps can improve the fabric’s aesthetics, durability, and compatibility with other materials.

Overall, the production of carbon fiber fabric involves precise control of temperature, pressure, and material composition to ensure a high-quality and consistent final product. The resulting fabric exhibits remarkable strength-to-weight ratio, high stiffness, and excellent resistance to corrosion and impact, making it suitable for a wide range of applications in industries such as aerospace, automotive, sports, and construction.

Practical uses for carbon fiber fabric in daily life

Carbon fiber fabric is a highly sought-after material in the fashion industry due to its combination of style and durability. Renowned fashion houses like Gucci, Louis Vuitton, and Chanel consistently release new designs of clothing and apparel, including T-shirts, jackets, trousers, and various accessories, all made from carbon fiber fabric.

Moreover, carbon fiber finds extensive use in numerous industries such as aerospace, construction, automotive, and medical. Its impressive strength-to-weight ratio and resistance to corrosion make it an ideal choice for applications in these sectors.

More specifically, it refers to providing additional information or elaborating on a particular topic or statement.

- Medical industry: Carbon fiber is involved in the manufacturing of artificial body parts such as knee joints, heart valves, etc. and surgical instruments. Carbon fiber fabrics are also used to make hospital bed linens, providing more comfort for patients.

- Sports and recreation industry: Sports products such as tennis rackets, golf clubs, cricket bats, fishing rods and other sports equipment often use carbon fiber for added strength and durability.

- Aerospace: Carbon fiber is widely used in the manufacture of aircraft parts such as hulls, propellers, etc. and spacecraft due to its light weight and high strength, helping to reduce weight and increase safety.

- Automotive Industry: In the automotive industry, carbon fiber is used to make car frames, bodies, and other components to reduce weight and increase performance.

- High-tech products: Carbon fiber is often used in the production of parts for electronics, computers and other technological devices, such as camera lenses, computer cases or anti-static protection devices.

- Consumer products: Carbon fiber fabrics are also used in the manufacture of consumer products such as suitcases and handbags, furniture, shoes and other everyday items.

Carbon fiber fabric has a wide range of applications in various aspects of human life. This versatile material is used in numerous industries, including aerospace, automotive, sports and recreation, construction, and even fashion.

In the aerospace industry, carbon fiber fabric is highly valued for its lightweight and high-strength properties. It is used extensively in the manufacturing of aircraft components such as wings, fuselage panels, and structural reinforcements. The use of carbon fiber fabric in aerospace helps reduce the overall weight of the aircraft, resulting in improved fuel efficiency and increased flight performance.

In the automotive industry, carbon fiber fabric is employed to enhance the strength and durability of vehicles while reducing their weight. This innovative material is utilized in the production of car frames, body panels, and interior components. By integrating carbon fiber fabric into car manufacturing, automakers are able to achieve better fuel economy, enhanced safety, and improved handling.

Moreover, carbon fiber fabric finds its way into sports and recreation activities. It is widely used in the production of sporting equipment such as tennis rackets, golf clubs, bicycles, and fishing rods. The use of carbon fiber fabric in these products provides athletes and enthusiasts with enhanced performance, increased maneuverability, and better shock absorption.

In the construction industry, carbon fiber fabric is utilized for reinforcing structures like bridges, buildings, and pipelines. It significantly improves the strength and resilience of these structures, making them more resistant to earthquakes, storms, and other environmental hazards. Additionally, carbon fiber fabric is used in the rehabilitation and strengthening of old structures, prolonging their lifespan and ensuring structural integrity.

Even in the fashion industry, carbon fiber fabric has made its appearance. Designers and fashion houses are incorporating this futuristic material into clothing and accessories, creating unique and avant-garde designs. Carbon fiber fabric offers a modern aesthetic, along with its desirable qualities such as lightness, flexibility, and durability.

In conclusion, carbon fiber fabric has become an indispensable material in various aspects of our lives. Its wide range of applications in industries like aerospace, automotive, sports, construction, and fashion highlights its versatility and the numerous benefits it brings. From improving aircraft performance to enhancing sporting equipment, carbon fiber fabric continues to revolutionize different sectors, making our lives safer, more efficient, and more stylish.

summary

The above passage provides fundamental information about Carbon fiber fabric and also aims to address the question of its durability. By reading this article, readers will gain valuable knowledge about this material. Additionally, it suggests staying updated with the News section of Fashion Bandung to stay informed about new trends and learn more about clothing materials.

Welcome to Fashion Bandung, your ultimate destination for fashionable clothing for men! Our store is dedicated to providing you with the latest trends and styles in men’s fashion. Whether you’re looking for casual wear, formal attire, or accessories to complement your outfit, we have it all.

At Fashion Bandung, we understand the importance of staying on top of the latest fashion trends. That’s why we constantly update our inventory to bring you the freshest and most stylish clothing options. Our collection includes a wide range of items such as shirts, t-shirts, trousers, jeans, jackets, suits, shoes, and more.

We believe that fashion is a powerful form of self-expression, and we want to help you showcase your personal style through our curated selection of clothing. Our team of fashion experts carefully handpicks each item to ensure that it meets our high standards of quality and style.

Our customer satisfaction is our top priority, and we strive to provide you with an exceptional shopping experience. Our staff is friendly, knowledgeable, and always ready to assist you in finding the perfect outfit. Whether you need help with styling advice or selecting the right size, we are here to help.

So why wait? Visit Fashion Bandung today and discover the latest fashion trends for men. Upgrade your wardrobe and elevate your style with our exclusive collection. We look forward to serving you and helping you look your best for any occasion.

Please click on the link below to access additional information:

– See more: [link here]

Editor: Ngo Thi Hong Nga is a proficient and experienced editor with a strong command of the English language. With a keen eye for detail and a deep understanding of grammar and punctuation rules, Nga ensures that written content is polished and error-free. Nga’s expertise lies in refining sentences, enhancing clarity, and improving overall readability. With a commitment to meeting deadlines and delivering high-quality work, Nga consistently strives to provide clients with the best possible editing services.