In addition to popular stretch fabrics like cotton and Lycra, mesh fabric is gaining attention from manufacturers. Find out more about this fabric and its applications in today’s life. Read the article below for all the details.

1. What is mesh fabric?

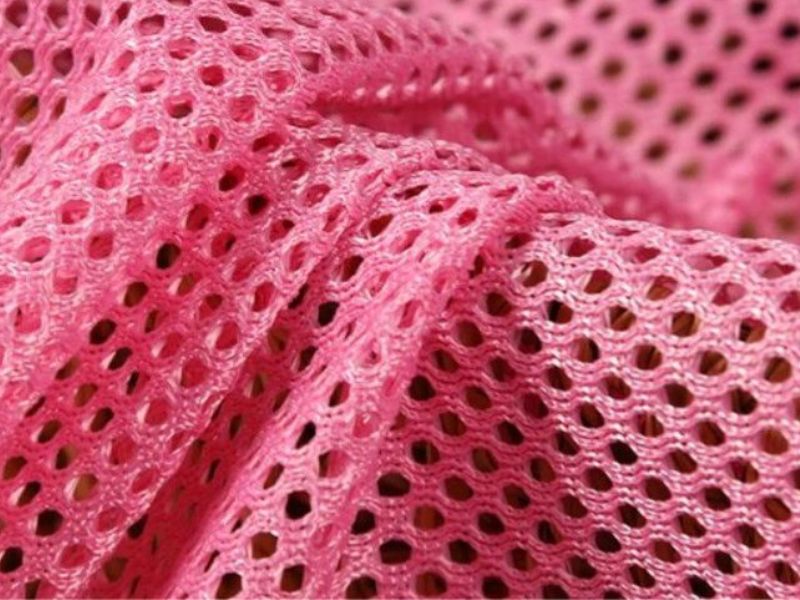

Mesh fabric is a type of fabric that is primarily made up of PVC (polyvinyl chloride), polyester, and PP (polypropylene). This fabric is known for its four-way stretch, which allows for a comfortable fit and flexibility for the user. The primary advantage of mesh fabric is its ability to provide excellent ventilation, allowing air to pass through and keep the wearer cool. Additionally, it is highly effective in absorbing sweat, making it an ideal choice for activewear and sports clothing. Overall, mesh fabric offers a combination of comfort, breathability, and moisture-wicking properties.

Mesh fabric is highly sought after for the production of summer clothing and sportswear due to its breathability and lightweight feel. It has become particularly popular in the form of floral mesh fabric, which offers a wide range of designs and patterns to cater to diverse consumer preferences. These variations in design ensure that consumers can find the perfect floral mesh fabric that best suits their individual needs and preferences.

Mesh fabric is commonly utilized in the production of various beach items such as beach hammocks, plastic towels, fabric nets, and more.

Mesh fabric is a type of textile that is characterized by its open and porous structure. It is typically made by intertwining or knitting yarns or fibers to create a grid-like pattern with numerous small holes or apertures. This design allows for excellent breathability and proper ventilation, making it ideal for applications where airflow and moisture management are important. Mesh fabric can be found in various forms, such as clothing, footwear, sportswear, bags, and even in industrial applications like filtration systems. Its versatility, durability, and ability to provide comfort and airflow make it a popular choice in many different industries.

Process for manufacturing mesh fabrics.

Would you like to know more about the process of creating mesh fabric panels? Let me explain. Unlike traditional fabrics that are woven using the weft weaving technique, mesh fabric is made differently. It is crafted by heating PP or PVC plastic beads, which transforms them into a unique material with special properties. This distinctive fabric is then used to create panels with a mesh-like appearance.

The process of producing mesh fabric involves several steps. First, raw materials such as polyester or nylon yarns are obtained. These yarns are then spun into long strands.

Next, these yarns are woven together using a specific weave pattern to create the mesh structure. The weave pattern determines the size and shape of the holes in the fabric. This process is done using specialized weaving machines.

After the fabric is woven, it undergoes a finishing process. This includes treatments such as dyeing, bleaching, or printing to give the fabric its desired color and appearance.

Following the finishing process, the fabric is inspected for any defects or imperfections. Any issues found are addressed and corrected to ensure the final product meets quality standards.

Once the fabric passes the inspection, it is rolled and packaged for distribution. It is important to properly package the mesh fabric to protect it from damage during transportation.

Overall, the production process of mesh fabric involves spinning yarns, weaving, finishing, inspection, and packaging. Each step is critical to producing a high-quality mesh fabric that can be used in various applications such as clothing, upholstery, or industrial purposes.

The following is a detailed description of the process involved in producing mesh fabric:

1. Yarn Selection: The initial step in producing mesh fabric is selecting the appropriate type of yarn. The yarn can be made from various materials such as cotton, polyester, nylon, or a blend of fibers.

2. Yarn Preparation: Once the yarn type is determined, it undergoes a preparation process. This involves cleaning, twisting, and winding the yarn onto bobbins or cones for further processing.

3. Knitting: The prepared yarn is then fed into a knitting machine. The machine uses specialized needles to interlock the yarn, creating a mesh structure. The specific knitting pattern can vary depending on the desired mesh design.

4. Dyeing and Printing: After the fabric is knitted, it undergoes dyeing or printing processes to add color or patterns. This step is important to achieve the desired aesthetic appeal of the final product. Different dyeing techniques, such as direct or reactive dyeing, can be used.

5. Finishing: Once dyed or printed, the mesh fabric undergoes various finishing treatments. This can include processes like washing, bleaching, or applying special coatings to enhance its characteristics. Finishing also helps to improve the fabric’s durability, softness, and resistance to factors like wrinkling or shrinkage.

6. Inspection and Quality Control: Throughout the production process, the mesh fabric is regularly inspected to ensure that it meets the required quality standards. This includes checking for any defects, color consistency, and measurement accuracy.

7. Cutting and Sewing: Depending on the intended use, the mesh fabric may be cut into specific shapes and then sewn together to create products like clothing, bags, or upholstery. Attention to detail is crucial in this step to ensure proper alignment and stitching.

8. Final Inspection and Packaging: After the cutting and sewing process, the finished products undergo a final inspection to ensure they meet the desired specifications. This includes checking for any manufacturing flaws, proper stitching, and overall appearance. Once approved, the products are carefully packaged for distribution and sale.

Overall, producing mesh fabric involves a series of steps ranging from yarn selection to final packaging. Each step requires precision and attention to detail to produce a high-quality and visually appealing fabric suitable for various applications.

- First, people will take PVC or PP plastic granules that have been carefully tested for composition and quality and heat them at high temperatures.

- Next, they are passed through a mesh system with tiny holes to roll and bond them into a flat fabric mold. This is the initial shaping step of the fabric.

- Next is the fabric shaping step, in this step the fabric fibers are passed through a mold to create a fabric with a predetermined shape and size. Thanks to that, the product achieves the desired shape and firmness.

Mesh fabric is created using a meticulous and precise weaving process that adheres to professional standards. It utilizes cutting-edge technology, making it one of the most technologically advanced fabric options available today.

3. Advantages of mesh fabric

“Is mesh fabric a reliable choice?” is a question that garners significant interest among consumers. This versatile material offers numerous notable advantages, making it a preferred option for many individuals. Some key benefits of mesh fabric include:

There are several advantages to using mesh fabric. Firstly, mesh fabric is highly breathable, allowing for proper air circulation. This makes it an ideal choice for clothing and accessories that need ventilation, such as sportswear or outdoor gear. Additionally, mesh fabric is lightweight, which adds to its comfort and ease of use. It is also known for its durability, as it can withstand regular use and frequent washing without losing its shape or integrity. Moreover, mesh fabric offers a certain level of flexibility and stretchability, making it suitable for use in products that require movement and flexibility, like activewear or upholstery materials. Lastly, mesh fabric comes in a variety of colors and patterns, providing ample options for design and aesthetic preferences.

- Create comfort for the wearer: Has 4-way stretch, good sweat absorption, creating a cool feeling for the user.

- Durable: Non-woven fabric products, lightweight fabrics are made from pure plastic fibers with high durability, so during use, there is no need to worry about breaking or tearing like other fabrics. In addition, this fabric material has very good load-bearing capacity, so it can be designed with separate thicknesses and thinnesses to best meet the needs of consumers.

- Highly aesthetic: Because it is woven with plastic, mesh fabric can be used in a variety of colors. Because it has many beautiful plastic colors, this fabric has great appeal to consumers. They help increase the aesthetics of design products.

- Easy to use: Unlike synthetic fabrics, mesh fabric can be easily rolled up because of its high flexibility, making it convenient to use in many situations.

- Easy to clean: Because it is made from plastic, products made from this fabric are not difficult to clean, are waterproof, easy to wipe and dry quickly. Even if washed many times, the quality and durability of the fabric will not be reduced.

The practical uses of mesh fabric in everyday life.

Due to its numerous advantages, the use of mesh fabric has become widespread in various industries. One such field is the fashion industry, where mesh fabric has gained immense popularity as a material for clothing production. It is commonly used in the making of items like t-shirts, sports shorts, and summer clothes. Additionally, mesh fabric is extensively used in other applications such as beach hammocks and plastic towels. Its versatility and durability make it a preferred choice for many consumers.

The use of mesh fabric can be seen in various applications that are part of our daily lives. Mesh fabric is a versatile material that offers numerous benefits and functionalities across different industries and activities.

In the fashion industry, mesh fabric is commonly used in sportswear and athletic clothing. It provides flexibility and breathability, allowing airflow to keep the wearer cool and comfortable during physical activities. Mesh fabric is also used in the creation of lingerie and intimate apparel, providing a lightweight and visually appealing texture.

In the field of home decor, mesh fabric finds its application in window treatments, such as curtains and blinds. The open weave structure of the mesh fabric allows natural light to filter through while providing privacy. Additionally, mesh fabric is utilized in the creation of furniture upholstery, adding a modern and contemporary touch to living spaces.

Mesh fabric is also widely used in the automotive industry. It can be found in the design of car seats and interiors, providing improved airflow and ventilation. The breathable nature of mesh fabric helps in reducing discomfort caused by long drives or hot weather conditions.

Furthermore, mesh fabric is extensively used in the sports industry. It is commonly seen in the production of sports equipment, such as bags, backpacks, and shoes. The durability and lightweight properties of mesh fabric make it ideal for storing sports gear and allowing proper ventilation to prevent odor and moisture buildup.

The medical field also benefits from the application of mesh fabric. It is used in surgical procedures, particularly in hernia repairs and other types of surgical meshes. The porous and sterile nature of mesh fabric aids in tissue regeneration and helps in providing support during the healing process.

Overall, the applications of mesh fabric in various aspects of daily life are vast and diverse. Its properties of breathability, flexibility, durability, and aesthetic appeal make it a preferred choice in industries ranging from fashion and home decor to automotive and medical fields.

In this article, Fashion Bandung has provided comprehensive answers to all questions related to mesh fabric. Readers can find all the relevant information they need to know about this fabric. We hope that this information will be beneficial for readers as they can gain a deeper understanding of the fashion industry.

Fashion Bandung is a clothing brand that specializes in providing fashionable clothing options for men. With a focus on style, quality, and versatility, Fashion Bandung offers a wide range of clothing items that cater to various tastes and preferences. Whether you are looking for casual wear, formal attire, or trendy accessories, Fashion Bandung strives to provide men with stylish options that allow them to express their individuality and stay ahead in the fashion game. With attention to detail and a commitment to providing the best in men’s fashion, Fashion Bandung aims to be the go-to brand for those seeking stylish and modern clothing choices.

The person responsible for editing the content is Nong Thi Nhung. They have the role of reviewing and making necessary revisions to ensure the quality and clarity of the material. Their expertise lies in language proficiency, grammar, formatting, and overall coherence. Nong Thi Nhung has the task of enhancing the text’s readability, accuracy, and effectiveness in delivering the intended message.