Banana fiber fabric is a surprising addition to the fashion industry, being used in garments instead of just food processing. Let’s explore this unique fabric in the article below!

What is banana fiber fabric? Different types of banana peel fibers.

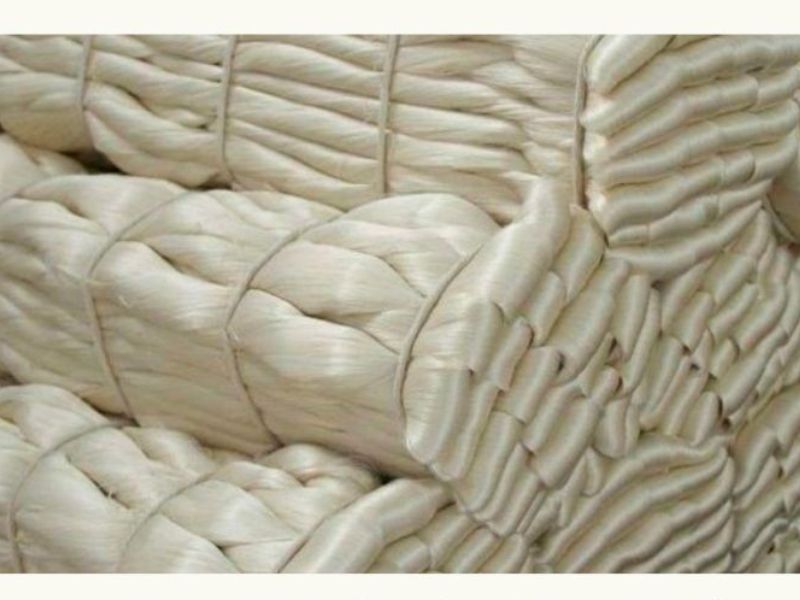

Banana fiber fabric is a type of fabric that is made from the fibers found inside and outside of banana stems. Unlike the soft and edible part of the banana that we typically eat, the fibrous part of the banana plant can be extracted and used to create textiles. Similar to other plants like jute or hemp, banana stems and grass also possess fibers that can be used in the production of textile products.

In recent times, the textile industry has started to recognize the potential of a method that has been in existence for centuries: using banana fibers to create sustainable fashion. Each year, a staggering number of banana trees are discarded, leading to substantial waste. However, by extracting and weaving the fibers from these trees, humans have the opportunity to considerably reduce the amount of environmental waste. Additionally, another advantage of using banana fiber in fabric production is its rapid decomposition, making it an eco-friendly choice.

Banana fiber fabric is a textile material made from the fibers extracted from the stem of the banana plant. The manufacturing process involves stripping the plant’s stem of its outer layers and extracting the long, flexible strands of fiber from the inner layers. These fibers are then processed and spun into yarn, which is woven or knitted to create various types of fabric. Banana fiber fabric is known for its durability, breathability, and moisture-wicking properties, making it suitable for a wide range of applications in the textile industry.

There are currently four popular types of banana fiber available in the market. These types include:

- Banana peel fiber outside: Along with raw fiber, this type of fiber has been used in industry for centuries. It is often used to produce ropes, outerwear, thick clothes, carpets,…

- Banana peel fiber inside: Creates a soft feel like silk fabric, complex production process, requires high cost.

- Banana silk: Banana silk fabric is the term used to refer to the inner banana peel fibers that have properties similar to silk, not a mixture of banana fiber and silk.

- Banana flower: This is a premium fabric made from the outer banana peel, with a cotton-like texture.

The origins and development of banana fiber fabric throughout history.

The Philippines holds the distinction of being the first country in the world to utilize banana stems and peels for the production of fabric in the garment industry. This achievement can be attributed to the significant advancements in banana farming on the island. As a result, the local population has honed their expertise in manufacturing banana fiber over several centuries, thereby preserving this unique skill.

The history of banana fiber fabric dates back several centuries. It is believed to have originated in regions where banana plants are abundant, such as Southeast Asia and the Pacific Islands.

Banana fiber fabric is made from the stalks of the banana plant, also known as the pseudostem. The stalks are processed to extract the fibers, which are then spun into yarns or threads. These yarns can be woven or knitted into various types of fabric.

Banana fiber fabric has been used for a wide range of applications throughout history. In ancient times, it was primarily used for making traditional clothing and household items. The fabric was valued for its durability, flexibility, and good moisture absorption properties.

As trade routes expanded, banana fiber fabric became popular in different parts of the world. It was particularly sought after in Europe during the 19th century, when it was used to make luxurious textiles for fashion and interior decoration. However, with the invention of synthetic fibers like nylon and polyester, the demand for banana fiber fabric gradually declined.

In recent years, there has been a renewed interest in sustainable and eco-friendly materials, leading to a resurgence in the use of banana fiber fabric. It is now being used in various industries, including fashion, home textiles, and even automotive interiors. The fabric is highly regarded for its natural properties, such as breathability, resistance to wrinkles, and biodegradability.

Today, banana fiber fabric is produced in several countries across the globe. It undergoes modern processing techniques to enhance its quality and make it suitable for different applications. The history of banana fiber fabric serves as a testament to the versatility and timeless appeal of this natural textile.

In addition to the Philippines, many other Asian countries have a long history of producing banana fiber fabric. This fabric has become highly esteemed in our country and is considered a speciality of Vietnamese agricultural culture. China also has a deep appreciation for this fabric, which they refer to as Giao Chi fabric. Currently, India is known as the top producer and distributor of high-quality large banana fiber fabric in the world.

Characteristics and traits of fabric made from banana fiber.

Next, I would like to provide you with more detailed information about the characteristics of Fashion Bandung. One notable characteristic of Fashion Bandung is the use of banana fiber fabric. This unique fabric is made from the fibers extracted from banana plants. It has gained popularity for its eco-friendly properties and natural texture. The banana fiber fabric is known for its durability and strength, making it suitable for a wide range of fashion garments and accessories. Additionally, this fabric has a lightweight and breathable nature, ensuring comfort for the wearer. Fashion Bandung embraces the use of banana fiber fabric as a sustainable and innovative material, adding a touch of natural beauty to their designs.

- Name: Banana fiber fabric is also known as banana silk fabric or musa fiber.

- Composition: The yarn is produced from fibers derived from the soft inner lining or the rougher outer lining of the banana peel.

- Has good breathability and moisture absorption, not easy to clump.

- Low heat retention, low elasticity.

- Often used to make lightweight clothing, men’s shirts long sleeve, tropical clothing, scarf, men’s sweater, men’s pantsdresses, hats, scarves, ropes, mats,…

Banana fiber fabric is a type of fabric that is made from the fibers extracted from the stalk of a banana plant. The properties of banana fiber fabric include strength, durability, and versatility. It is known for its excellent tensile strength, making it a strong and resilient material. Additionally, banana fiber fabric is lightweight and breathable, allowing for air circulation and comfort. It is also moisture-wicking, meaning it can absorb and disperse moisture quickly, keeping the wearer dry. Furthermore, banana fiber fabric has natural antibacterial properties, making it resistant to odor-causing bacteria. It is also hypoallergenic, making it suitable for those with sensitive skin. The fabric has a unique texture, with a slight sheen and a natural unevenness that adds character to the final product. It is also biodegradable and eco-friendly, as it is made from a renewable and sustainable resource. Overall, banana fiber fabric offers a combination of strength, comfort, and environmental friendliness, making it a desirable choice in the textile industry.

- The fiber content in bananas provides ventilation, acts as a natural solvent, and keeps the wearer’s body cool, especially on hot days.

- It feels soft and supple. While not as smooth as rayon or cotton, it has a natural shimmer that gives it a silk-like look.

- Clothes made from banana fiber feel comfortable and do not irritate the skin.

- Has high color fastness, helps preserve the beauty of the product’s color for a long time.

- The fabric has very good strength and tensile strength and can be easily adjusted for toughness.

- If the inner layer of banana fiber fabric feels soft and breathable, the outer layer has a rough structure that creates an appearance somewhat similar to burlap or cotton.

- The fabric is completely biodegradable so it is very friendly to the natural environment.

The characteristics and properties of banana fiber fabric are as follows:

1. Strength: Banana fibers have high tensile strength, making the fabric durable and resistant to tearing. This makes it suitable for various applications.

2. Eco-friendly: Banana fiber is a natural and renewable resource, making it an environmentally friendly choice for fabric production. It is biodegradable and does not contribute to pollution.

3. Breathability: The fabric made from banana fibers has excellent breathability, allowing air to flow through and keeping the wearer cool and comfortable. It is perfect for warm climates.

4. Moisture absorption: Banana fiber fabric has good moisture absorption properties. It can absorb sweat and moisture from the body, keeping the wearer dry.

5. Softness: Despite being strong, banana fiber fabric is soft and smooth to the touch. It provides comfort and is gentle on the skin.

6. Anti-bacterial properties: Banana fiber fabric has natural anti-bacterial properties, inhibiting the growth of bacteria and preventing odors. This makes it ideal for clothing and bedding.

7. Versatility: Banana fiber fabric can be easily blended with other fibers such as cotton or silk to enhance its properties. It is also versatile in terms of dyeing and can be transformed into various colors and patterns.

8. UV resistance: Banana fiber fabric offers good protection against harmful UV rays. It can block a significant amount of sun rays, providing added protection to the wearer.

9. Insulation: Banana fiber fabric has good thermal insulation properties, helping to regulate body temperature in both hot and cold climates.

10. Lightweight: The fabric is lightweight, making it comfortable to wear. It does not add unnecessary bulk and allows for ease of movement.

The process of producing fabric from banana fiber.

Would you like to know more about the origins of banana fiber fabric and how it is created? Follow the information provided below to gain insights into the fascinating process of manufacturing this unique fabric.

Initially, the process begins by extracting the fibers from both the banana peel and stem, effectively separating them from the parts that are not utilized. This crucial step involves employing a range of techniques. For instance, one approach consists of immersing the banana peel in either water or specific chemical substances to facilitate the softening and subsequent separation of the different components.

After the fibers have been separated from each other, they are gathered and subjected to a drying process. During this stage, both the outer and inner fibers are kept together as it becomes challenging to separate them while they are still wet.

After the fibers have completed the drying process, they are meticulously categorized into various groups based on their quality attributes. Among these groups, the highest quality fibers are often sought after as a viable alternative to silk due to their exceptional properties.

- Step 4: Spinning and weaving

Once the fibers have been separated and organized, they undergo a process of spinning to create yarn. Afterward, the yarn is dyed to add color. These dyed fibers are then woven into a range of products, including clothing, decorations, and fashion accessories. In the past, this entire process was predominantly carried out manually, resulting in limitations on output. However, with advancements in scientific knowledge, the process has become more modernized, leading to increased output and higher quality banana fiber fabric.

The process of producing banana fiber fabric involves several steps. First, the banana plants are harvested and the outer layers of the stem are removed. The remaining inner layers, called the sheath, are then soaked in water to soften them.

Next, the sheaths are scraped to remove any remaining pulp and then dried. Once dried, the sheaths are manually or mechanically decorticated to extract the long fibers.

After decortication, the fibers are cleaned to remove any impurities and then they undergo a process called retting, which involves soaking them in water or exposing them to moisture for a specific period of time to further separate the fibers.

Once retted, the fibers are washed and dried again. They are then ready to be spun into yarn or twisted together to make thread.

Finally, the yarn or thread is woven into fabric using traditional techniques or modern machinery, depending on the production scale. The resulting banana fiber fabric can be used for various applications, such as clothing, upholstery, or even industrial uses.

Pros and cons of fabric made from banana fibers.

Why choose banana fiber fabric? In this article, Fashion Bandung explores the various advantages and disadvantages of using this unique type of fabric. Find out more about the characteristics and properties of banana fiber fabric in the following sections.

Advantage

- Has higher durability than many fabrics, is resistant to cracking and has good tensile strength.

- Fabric made from banana trees – a renewable resource and very environmentally friendly. The production process does not pollute the environment, does not use toxic chemicals.

- Has good moisture absorption and ventilation, creating a cool, dry, comfortable feeling when used.

- The fabric has natural antibacterial properties, helping to prevent the growth of bacteria and odors. In particular, it limits mold, helping the product maintain its aesthetic beauty.

- Banana fiber utilizes parts of the banana plant, thus avoiding material waste. It is an ideal alternative to many other synthetic and natural fibers. This helps reduce the amount of waste released into the environment every year.

There are several advantages of using banana fiber fabric.

Firstly, banana fiber fabric is a sustainable and eco-friendly material. It is made from the stalks of banana plants, which are a renewable resource. The production process of banana fiber fabric involves minimal chemical treatments, which makes it a more environmentally friendly alternative to synthetic fabrics.

Secondly, banana fiber fabric is biodegradable. This means that when it is disposed of, it will naturally decompose without leaving any harmful residue behind. This is important in reducing the environmental impact of textile waste.

Additionally, banana fiber fabric has excellent moisture absorption properties. It can absorb and release moisture more quickly than cotton, keeping the wearer cool and dry. It is also a breathable fabric, allowing air circulation and preventing the buildup of odor-causing bacteria.

Furthermore, banana fiber fabric is known for its strength and durability. Despite being a lightweight material, it is resistant to tearing and has high tensile strength. This makes it suitable for various applications, including clothing, accessories, and home furnishings.

Lastly, banana fiber fabric has natural antibacterial properties. It contains a substance called lignin, which has antimicrobial properties. This makes it a hygienic choice for products that come into contact with the skin, such as clothing and towels.

In conclusion, banana fiber fabric offers several advantages. It is sustainable, biodegradable, moisture-absorbent, strong, and has natural antibacterial properties. These qualities make it a versatile and environmentally friendly option for various textile applications.

Defect

Although banana fiber fabric offers numerous advantages, it is not without its limitations. These limitations include the following:

- Lower elasticity compared to cotton, spandex,… leading to limited flexibility and comfort when wearing clothes.

- The fabric wrinkles easily and is more difficult to iron than many other fabrics, requiring users to take special care when washing and ironing the product, spending a lot of time and effort to maintain the beauty of the fabric.

- Products made from banana fiber fabric are more expensive than similar products made from other common fabrics because the production process requires high technology and special materials.

One of the drawbacks of using banana fiber fabric is that it has a relatively low tensile strength compared to other natural fibers such as cotton or silk. This means that it may be more prone to tearing or breaking under stress or strain.

Additionally, banana fiber fabric has limited flexibility and elasticity, which can limit its range of applications. It may not be suitable for garments or products that require a high degree of stretch or flexibility.

Another disadvantage is that banana fiber fabric can be difficult to dye or color. The fibers have natural pigments that are not easily removed or altered, making it challenging to achieve vibrant or consistent colors.

Furthermore, banana fiber fabric tends to have a rough and coarse texture, which may not be comfortable against the skin. It can feel abrasive and may cause irritation or discomfort when worn next to the body.

Lastly, banana fiber fabric is not readily available in large quantities. Since banana plants only yield a limited amount of fiber, it may be more expensive or difficult to source compared to other fabrics. This limited availability can also restrict its use in mass production or large-scale manufacturing.

5. Practical uses of banana fiber fabric in everyday life

Currently, banana fiber fabric is being utilized in various fields and industries. It is finding applications in areas such as:

- In the fashion industry: Banana fiber is used to produce fabrics, high-end clothing or accessories such as scarves, gloves,…

- In the field of interior and household appliances: People use banana fibers to create ropes, doormats, wall stickers,… or tropical-style decorations.

- In the automotive industry: Banana fiber is the material for covering spare tires of many famous car brands such as the second generation Mercedes-Benz A-class. Because this material has high tensile strength, anti-grip, resistant to impact or exposure to the environment such as UV rays, chemicals,…

- In addition, banana fiber fabric is also used to produce environmentally friendly and low-cost sanitary napkins by the International Institute for Environment and Development.

One of the various successful applications of banana fiber fabric can be seen in our daily lives. This eco-friendly and versatile fabric has found its way into different aspects of our routines. From clothing to home furnishings, banana fiber fabric offers numerous benefits and functionalities.

In the fashion industry, banana fiber fabric has gained popularity due to its unique properties. It is lightweight, breathable, and has excellent moisture-wicking capabilities, making it a suitable choice for comfortable and sustainable clothing. Many designers and brands have started incorporating this fabric into their collections, offering consumers stylish and eco-friendly clothing options.

Aside from clothing, banana fiber fabric has also found its way into home furnishings. Its strength and durability make it a great choice for upholstery fabrics. Sofas, chairs, and curtains made from banana fiber fabric not only provide a natural and elegant touch to home interiors but also contribute to sustainability efforts.

Furthermore, banana fiber fabric has applications in the field of agriculture as well. It can be used as a biodegradable alternative to plastic mulching films. These films, when placed over the soil, help control weed growth and conserve moisture. Banana fiber mulching films are not only environmentally friendly but also renewable, as they can be decomposed and returned to the soil without causing harm.

Another practical application of banana fiber fabric is in the production of paper. The long and strong fibers of the banana plant make it suitable for papermaking. Banana fiber paper is used in various industries, including packaging, stationery, and art supplies. It offers a sustainable alternative to traditional paper made from trees.

In conclusion, the applications of banana fiber fabric in daily life are diverse and ever-expanding. From clothing and home furnishings to agricultural and industrial uses, this eco-friendly fabric offers numerous benefits while contributing to sustainable practices. Its versatility, durability, and eco-friendly nature make it a valuable material choice for a range of applications.

What are the best ways to maintain and protect garments made from banana fiber?

Here are some tips for caring and maintaining banana fiber fabric the right way:

- Read the label carefully.: First, check the care label on the product to understand the specific care instructions. This will help limit damage to the fabric due to using the wrong care method.

- Hand wash or gentle machine wash: This fabric is very sensitive to high pressure and friction, so hand washing is preferred or if using a washing machine, set the washing mode to gentle. In addition, cold or warm water should be used to help prevent the banana fibers from shrinking.

- Use mild detergent: When washing clothes made from banana fiber, you should use a mild detergent, avoid using strong detergents or anti-wrinkle detergents as they can damage the product.

- Avoid using stain remover directly.: For stubborn stains, you should not use stain remover directly on the fabric surface. Instead, you just need to dilute a small amount of mild detergent in water and pour it on the stain before washing.

- Limit exposure to strong light: If exposed to strong light, banana fiber fabric is very easy to fade, so avoid direct sunlight and keep in a cool place.

- Limit the use of dryers: This fabric tends to shrink when exposed to high temperatures. Therefore, you should let them dry naturally or dry them in a cool space.

- Iron the product at low temperature.: If you need to iron your clothes, set the temperature to the lowest setting to avoid damaging the product. You should also use a cloth to cover the fabric so that it does not come into direct contact with the iron.

Here is a detailed guide on how to properly care for and preserve banana fiber fabric:

1. Washing: Banana fiber fabric should be hand washed or machine washed on a gentle cycle with cold water. Avoid using harsh detergents or bleach, as they can damage the fabric. Instead, opt for mild and natural cleaning agents.

2. Drying: After washing, gently squeeze out excess water from the fabric. Do not twist or wring the fabric. Instead, lay it flat on a clean towel and roll it up to remove any remaining moisture. Finally, hang the fabric in a shaded area to air dry. Direct sunlight can cause fading and damage the fibers.

3. Ironing: To remove wrinkles, iron the banana fiber fabric on a low or medium heat setting. It is recommended to place a thin cotton cloth over the fabric before ironing to protect it from direct heat. Avoid using steam, as excessive moisture can weaken the fibers.

4. Storage: When not in use, store banana fiber fabric in a cool and dry place. Avoid folding or stacking it with heavy items, as this can cause creasing and deformation. Instead, roll the fabric and store it in a breathable bag or container to prevent dust accumulation and maintain its shape.

5. Maintenance: Banana fiber fabric is susceptible to pests such as moths and silverfish. To protect it, periodically inspect the fabric for any signs of infestation. If necessary, use natural insect repellents or store the fabric with dried neem leaves, cedar chips, or lavender sachets.

6. Avoiding moisture: Banana fiber fabric should be protected from excess moisture. Avoid wearing it in humid conditions, as excessive humidity can cause the fabric to become damp and lose its structural integrity. If the fabric does get wet, dry it promptly to prevent any potential damage.

By following these care instructions, you can prolong the life of your banana fiber fabric and ensure it maintains its natural beauty and durability for years to come.

The potential for developing banana fiber fabric is being explored.

The recognition of banana fiber fabric as a valuable asset in the garment industry is not a mere coincidence. Its remarkable qualities position it as a shining star within this sector. In order to fully comprehend the trajectory of this fabric and its significance, let us delve into its immense potential for development in the near future.

The development potential of banana fiber fabric is a topic of interest and exploration. Researchers and industry professionals are studying the properties and possibilities of utilizing banana fibers as a textile material. In recent years, there has been a growing awareness of the importance of sustainable and eco-friendly materials in various industries, including fashion and textiles. Banana fiber, derived from the stem of the banana plant, offers potential as a sustainable alternative to traditional fabrics such as cotton or synthetic fibers.

Banana fiber has several unique properties that make it attractive for textile applications. It is lightweight, strong, and has good tensile strength. Additionally, it has moisture-wicking properties and is biodegradable. These qualities make it suitable for a range of applications, including clothing, home textiles, and industrial textiles.

The development potential of banana fiber fabric extends beyond its environmental benefits. The textile industry is constantly seeking innovative materials that can offer unique textures, patterns, and finishes. Banana fiber, with its natural sheen and luster, has the potential to create visually appealing fabrics. It can also be blended with other fibers to enhance its properties or create new textile blends.

Moreover, the production of banana fiber fabric has the potential to provide economic opportunities in regions where bananas are grown. The extraction of fibers from banana stems can be a source of income for farmers and communities. Consequently, the development of banana fiber fabric could contribute to sustainable growth and poverty reduction.

However, there are challenges that need to be addressed in order to fully exploit the development potential of banana fiber fabric. These include improving the efficiency of fiber extraction, developing cost-effective processing methods, and ensuring the scalability of production. Research and development efforts are ongoing to overcome these challenges and unlock the full potential of this renewable and versatile textile material.

- Sustainable fashion: Banana fiber is a great source of raw materials to promote sustainable fashion trends because of its durability and environmental friendliness. Nowadays, people are increasingly concerned about the impact of fashion on the environment. Therefore, banana fiber becomes an ideal choice for designers and consumers.

- Recycle, reuse: With the ability to be recycled and reused, banana fiber fabric has made a significant contribution to reducing the amount of fashion waste released into the environment. Recycling and reuse processes are increasingly developing to maximize the potential of this fabric.

In the above article, Fashion Bandung has shared valuable information about banana fiber fabric. This information will help readers gain a deeper understanding of fabrics and enable them to make informed choices when selecting products. The article also highlights the importance of supporting the sustainable fashion trend. By opting for banana fiber fabric, individuals can contribute to the promotion and growth of sustainable fashion.